Advantages

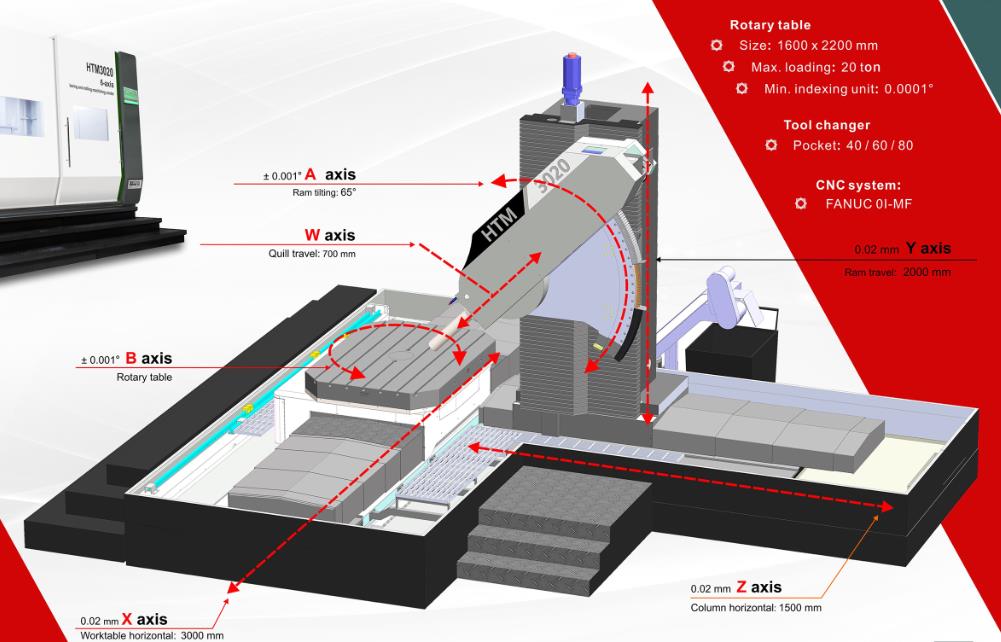

The 6-axis Boring and Milling Machining Center

—Best suitable for boring and precision milling of medium and large mechanical parts and molds

Specifications

| Model | Unit | HTM3020 | |

| Drilling capacity | Milling capacity | cc/min | 400 |

| Tapping capacity | - | M52x5 | |

| Travel | Worktable horizontal (X) | mm | 3000 |

| Ram Travel(Y) | mm | 2000 | |

| Column horizontal (Z) | mm | 1500 | |

| Quill diameter/travel (W) | mm | Φ130/700 | |

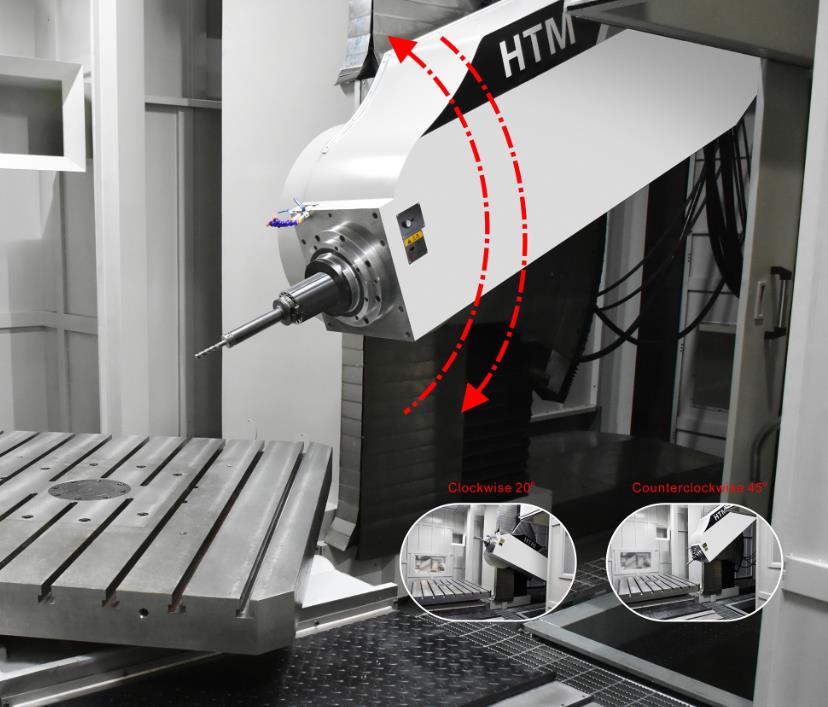

| Ram tilting angle (A) | ° | clockwise 20, counterclockwise 45 | |

| Spindle center to table top | mm | 0 to 2000 | |

| Spindle | Spindle bore taper | - | BT50 |

| Max. spindle speed | rpm | 2500 | |

| Speed | X/Y/Z Rapid traverse rate | m/min | 10 |

| W Rapid traverse rate | m/min | 4 | |

| Ram tilting speed (A) | rpm | 1 | |

| Worktable max. rotation speed (B) | rpm | 2 | |

| Power | Spindle motor | kW | 22/26(30min) |

| X axis servo motor | N.m | 38 | |

| Y axis servo motor | N.m | 38 | |

| Z axis servo motor | N.m | 38 | |

| W axis servo motor | N.m | 22 | |

| A axis servo motor | N.m | 30 | |

| B axis servo motor | N.m | 30 | |

| Total power requirement | kW | 78 | |

| CNC indexing worktable | Max. loading capacity | ton | 20 |

| Size (Length x Width) | mm | 2200x1600 | |

| Min. indexing unit | ° | 0.0001 | |

| Size & Weight | Floor space required | mm | 9200x7500 |

| Machine height | mm | 4950 | |

| Machine weight | ton | 40 | |

| CNC system | - | - | FANUC 0i-MF |

Design & specifications are subject to change without prior notice!

Design & specifications are subject to change without prior notice!Accessories

| HTM3020 | |

| Full guard |  |

| Lubricating system |  |

| Coolant system |  |

| Pneumatic system |  |

| Leveling screws and leveling wedges |  |

| AI contour coontrol II |  |

| FANUC 0i-MF system |  |

| Data Server |  |

| Ethernet |  |

| Service tools and tool box |  |

| Air blast through spindle |  |

| Air blast |  |

| Working light |  |

| Cycle indicator lamp |  |

| Chain type chip conveyor |  |

| Air cooler for electric cabinet |  |

| Chiller |  |

| Manual handle feed unit |  |

| Spindle orientation |  |

Design & specifications are subject to change without prior notice!

Design & specifications are subject to change without prior notice!Application Case